It seems DiyouPCB MKI has appeared again in some blogs, just a year after publishing the project first time and its funny because we do not know why.

Last week we began receiving congratulations messages so we searched "Diyouware" in google and we saw that we were present in important blogs like: 3ders.org, 3dPrint.com, Adafruit.com, Bricogeek.com, Imprimalia3D, Geeky-gadgets.com, etc.

Probably someone published the project in one of the blogs and then Internet spread it. Publicity and congratulations are always welcome, although it is about the old model. Anyway thanks very much for all!

Regarding our current project: “TwinTeeth - the PCB mini-factory”:

it runs according to the plan (that of course we change every day  ) so in February we will publish it.

) so in February we will publish it.

During the Christmas holidays we were very busy. We designed an inspection camera holder, we did more PCB printing testing and even had time to design and build a new FDM 3D printer since our Prusa Mendel is a little outdated.

The camera is fundamental to print and manufacture high-density PCBs because sometimes we can not appreciate the details at a glance. It allows determining precisely the home position and the most important thing: setting it when we change the toolhead as there may be slight variations each time we manipulate the printer. It also allows us to inspect in detail the quality of the jobs and see how evolves them on the fly.

Here you can see a photo of the camera holder and the camera.

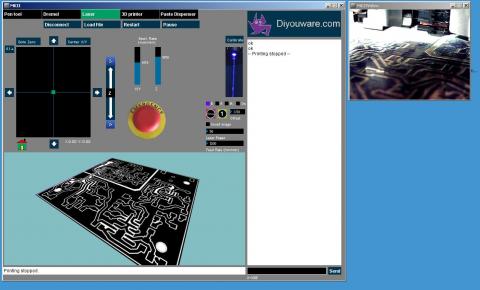

Below: the TwinTeeh’s Control Console. To the right, the live-video obtained with the camera.

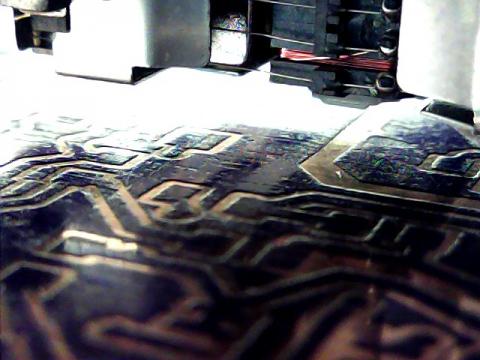

Next one a beatiful view of the PHR-803T lens coils above the PCB just printed.

About printing testing:

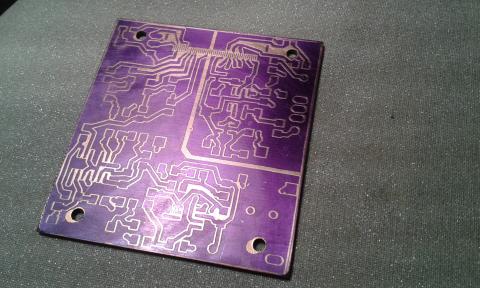

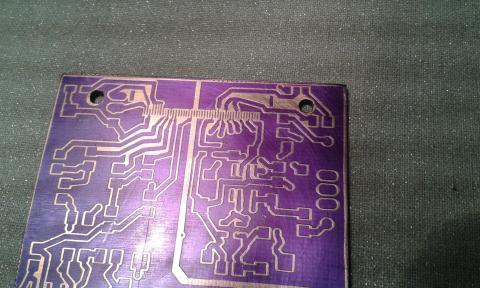

We had time to print some PCBs and every time we are obtaining better results and higher quality. At the same time we are discovering the best procedures to do it. We are already printing on two sides. This fixture bed helps us considerably to align them. It’s simple: we print the top PCB side, then turn it around and set it back on the fixture pins and then we print the bottom side. I remember how many hours I spent trying to align them in the almost complete darkness with traditional methods.

We are also changing some small details in the software. We want TwinTeeh to be very easy to use since we believe that any tool have to be user-friendly to be really useful.

Some photos:

You can see in the picture above that the printing has been shifted a little to the left. This is because we set wrongly the home position. After this test we decided to implement the camera. Also we cut the PCB just to fit the circuit and it is not a good idea: it is better to make it a little bigger.

Regarding the Prusa I3:

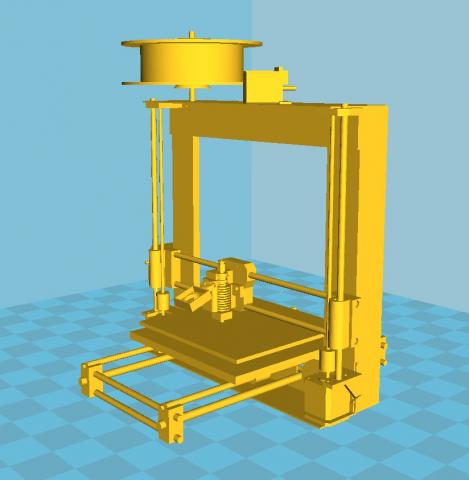

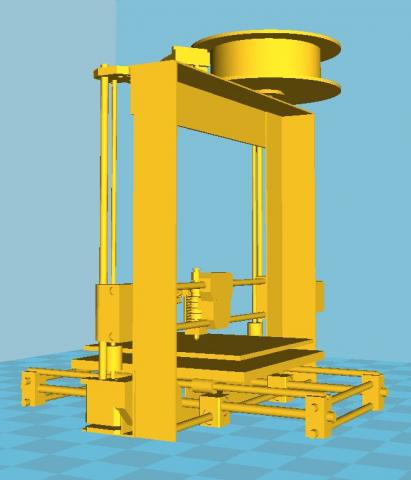

We have also improved the printer's rigidity ans stability and reduced costs replacing the aluminum frame with one built with aluminium L-shaped profiles. It is something similar to plywood “box type” models but alu. version (plywood proably is not the best material to build a 3D printer since it absorbs moisture). We adopted a bowden type extruder and an E3D hot-end.

We named it Diyouware I3 and it is already printing. We will post all the part files and blue-prints in case someone wants to make it.

Just if someone has read the post very fast: this is NOT TwinTeeh, it’s only another Prusa I3 3D printer…