Focus on focusing

We successfully finished the 3D printing tests and now we are focus on the Laser Toolhead, but first let me tell you how important is to level correctly the fixture plate.

As I said in the last post we developed some code to test the bed auto-levelling algorithm. This algorithm is in the firmwware and maintains the platform perfectly levelled while the robot is working.

The test is based on focusing the laser on the platform. We use the laser to measure how far is the platform in 36 surface points distributed on a 6x6 matrix.

To check if the bed auto-levelling algorithm works fine we did the test after and before leveling the platform.

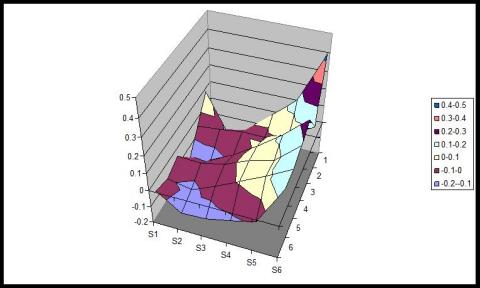

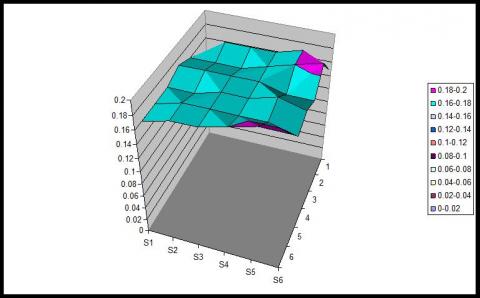

These are the results:

Fig. 1 – Test results without bed auto-levelling

Fig. 2 – Test results after auto-levelling calibration

Once the platform is calibrated the distance to the probe (laser head) is maintained most of the time in the range of 0.16 - 0.18 mm. Only in two points the measure was out of that scope. It means that most of the time the platform is levelled with an average precision of aprox. 0.05mm.

Accurate bed levelling is important for PCB engraving, PCB laser photoengraving and 3D printing. If we want to obtain good quality PCBs using laser photoengraving we need to focus the laser beam with precision. In our case we do it moving the pickup focus lens till we found the appropriate focus distance. But the lens servo has its limits and if the platform is not correctly levelled it’s impossible to focus the laser beam across the PCB.

So, now that we know that the platform is levelled we can focus on focusing.