New kid in town and first conductive ink testing

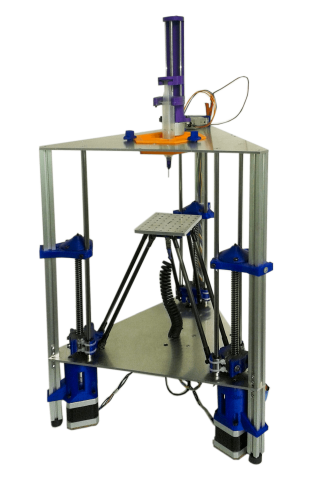

You guys probably already know that there is a new kid in town. It’s lovely, isn’t it?

It is the result of a collaboration agreement with Mecaduino. We already talked about these guys in other blog article.

We has named it TwinTeeth Plus, and changed the name of the original one to TwinTeeth Basic. The new model works in the same way than the original but with an aluminium framework.

Some people asked us: why another model?. Well, one reason is because we met Mecaduino people at the Maker faire and we promised to make something with their system.

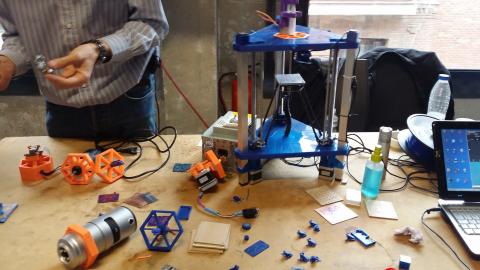

By the way, a picture of TwinTeeth Basic at the fair.

But main reason is that making the framework with aluminium parts we can save 3D printing time. Printing the plastic pieces of TwinTeeth Basic was taking us too much time.

It seems 3D printers make the hard work and meanwhile we can do other things, but it is not so obvious. We need to supervise them, and when printing 24 hours per day always are issues to solve. The triangle vertexes are really big for our 3D printers. They almost take up all the printing platform (200mmx200mm). Each vertex takes approx. three hours to 3D print. And we could not serve the kit’s demand.

Apart from that, the new printer has similar performance than the original, although is more robust, easier to assemble, and installing the toolheads is easier as well.

Conductive Ink

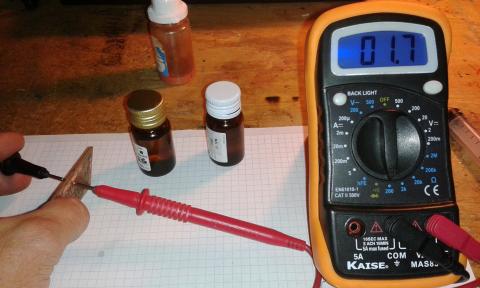

On the other hand, we found time to continue our researching with the nano-coopper particles.

We have been doing some experiments with the ink we brewed and the good news is that it has a good performance!. Testing results are not conclusive yet, but it seems it has a good conductivity: approx. 8.8Ω per linear cm (using our “cheap” multimeter).

We also filled some vias to see if we were able to obtain side-to-side conductivity with them. It was difficult to fill them because the ink is too fluid and drain on the other side. Maybe we should add some viscous agent to make it less fluid. Once put it inside we used a hairdryer to cure it.

After that we tested them and conductivity is also good.

So, we see feasibilty on the project. We still have to improve the formulations and also find a cheap source of copper nano-particles.

We received the copper oxide we ordered, but unfortunately we were wrong and ordered copper oxide (II) instead of (I). The difference is that first one is more oxidized and is more difficult (almost impossible) to reduce the oxygen and obtain the copper.

For now we are going to spend our precious ink in some experiments and then we will see.

That’s all.

Thanks!