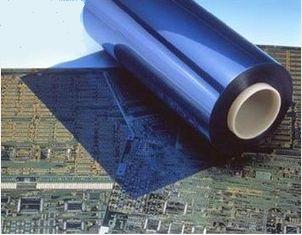

Dry-Film

Dry film is a polyester film coated with a polymer which is sensitive to ultraviolet light (Photoresist). It adheres by heat to the PCB and allows you to print circuits using any photolithography method. Once photosensitized, it is developed using an alkaline solution.

It is widely used at the professional level on the PCB industry and has a reasonable price (approx. $15-20$ per m2).

The PCB's manufacturing process using Dry-film is the following:

1.- Remove the inside protective film and paste it to the PCB using heat. You can use any air dryer or an iron. At the professional level most fabs uses a laminator.

2.- Place the PCB on the printer.

3.- Print the circuit.

4.- Remove the outside protective film from the Dry-Film+PCB.

5.- Introduce the PCB into the developer product. After a few minutes you will see the image of the circuit.

6.- Clean the PCB with water.

7.- Etch the PCB with your favourite acid.

8.- Finally eliminate the remnants of the dry-film (striping).

We use a type of Dry-film which has the following specifications:

- Type: negative

- Lamination temperature: 115 °C + /- 5 °C

- Color: Initial: light blue, Post-exposure: Blue

- Time post-exposure: 15 min recommended

- Developing time: 3-5 min @ 20-21° C

- Developing product: sodium carbonate 0.80 - 0.90 %

- Stripping product: sodium hydroxide, 1.5 - 3%

For more information: Instructables - Dry Film Photopolymer for making circuit boards

Get the Dry-film

There are several manufacturers and distributors of Dry-Film blue-color negative type which was the one we use it. You can buy it on the Internet or in specialized shops. You can also use any other film or photosensitive paint, but we only tested the Dry-film mentioned above.