DiyouPCB – Assembling the electronics

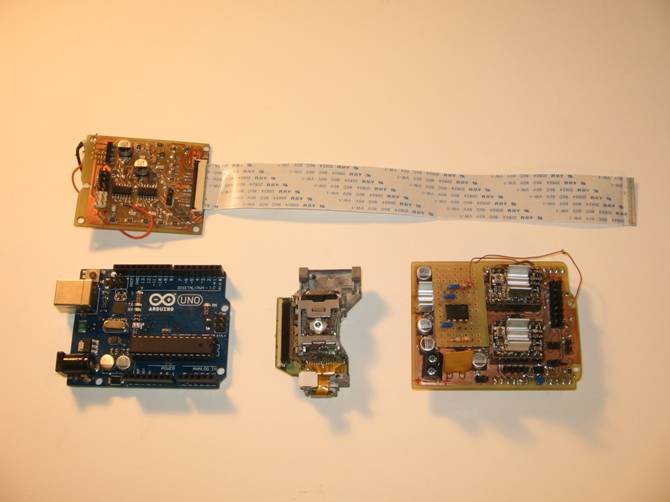

The printer electronics is composed of the following components:

- An Arduino UNO which acts as microcontroller.

- A Printer Controller Shield that is connected to the Arduino. Incorporates the drivers of the stepper motors (among other things).

- Two stepper motors drivers (Pololu A4988).

- A PHR-803T optical pickup.

- A Pickup Driver responsible for the interface between the PHR-803T and the Printer Controller Shield.

We have designed the Printer Controller Shield to be able to manage up to three stepper motors for three axis (X,Y,Z), but the printer only uses two: the X and Y axis For this reason you only need two stepper motors drivers.

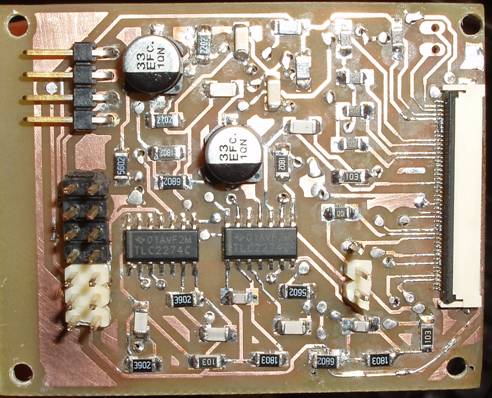

Next picture shows the Printer Controller Shield and the Pickup Driver prototypes, this latter with the FPC cable connected.

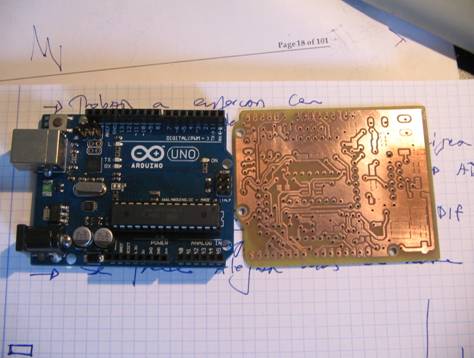

Attention: The pictures of this section show the prototypes of the electronics that are slightly different from the final versions.

Installing the Stepper Motor Drivers

The first thing to do is to install the stepper motors drivers. The drivers that we used are the well-known Pololu-A4988 . You can use the original ones or any of the clones that you will find on the web.

The drivers looks like this:

The pins strips and the IC radiator use to come uninstalled so the first thing is to solder the two pins strips and paste the radiator on the IC.

Attention: take care when you install the drivers on the shield, because if you install them incorrectly you will destroy them. They are also destroyed if you connect/disconnect motors while electronics is turned on.

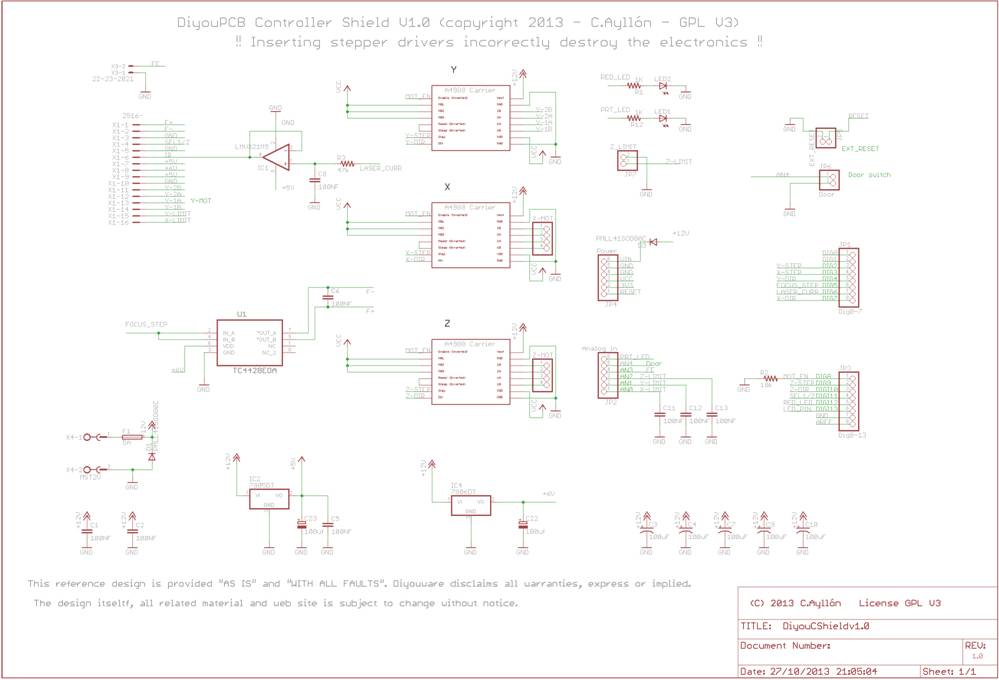

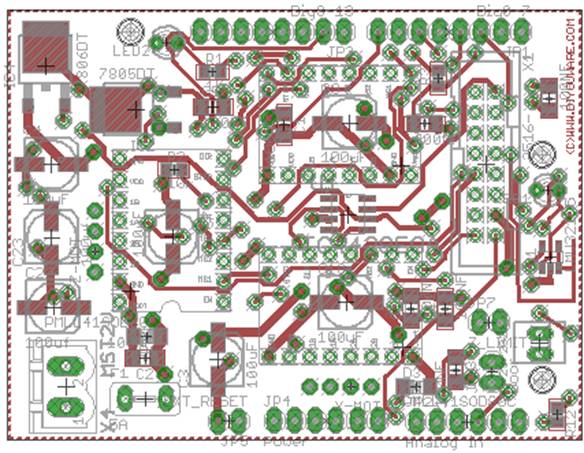

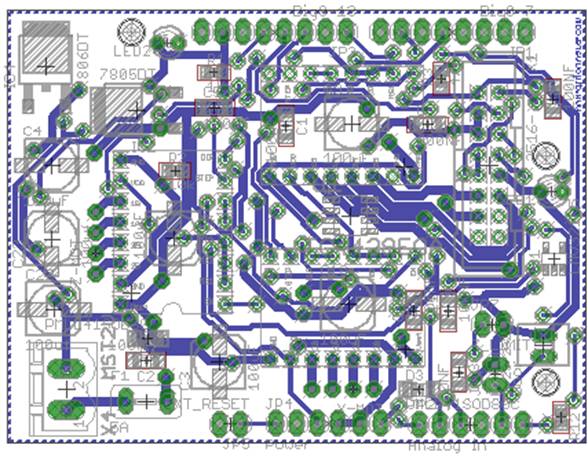

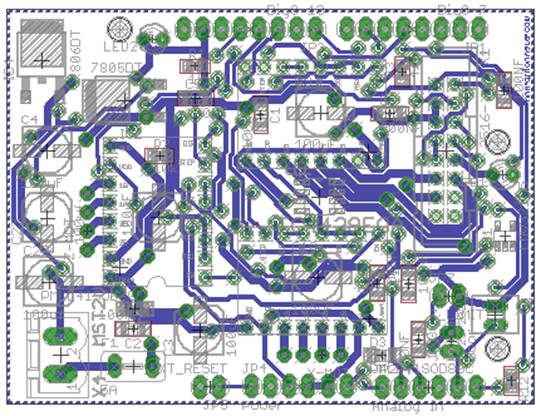

Assembling the Printer Controller Shield (PCS)

The PCS is an Arduino UNO shield responsible for hosting the stepper motors drivers, regulate the power supply and condition several signals.

It is not the aim of this tutorial detailing the construction of the PCS electronics as we assume that the person interested in building the printer will have those skills.

As guidelines we indicated the most important steps:

- Print out the PCB (unfortunately we cannot use the printer yet for this since we have not built )

- Manufacture the PCB (cutting, etching, drilling, etc. )

- Solder the components with special attention to polarities

- Solder the pins and connectors

- Place the IC radiators

- Check that everything is correct

Below you will see the bill of materials required to build the Printer Controller Shield.

|

Printer Controller Shield V1.0 |

|

|

|

Component |

Value |

Description |

|

C1 |

100nF |

Capacitor |

|

C2 |

100nF |

Capacitor |

|

C3 |

100uF |

Polarized Capacitor |

|

C4 |

100uF |

Polarized Capacitor |

|

C5 |

100NF |

Capacitor |

|

C6 |

100NF |

Capacitor |

|

C7 |

100uF |

Polarized Capacitor |

|

C8 |

100NF |

Capacitor |

|

C9 |

100uF |

Polarized Capacitor |

|

C10 |

100uF |

Polarized Capacitor |

|

C11 |

100NF |

Capacitor |

|

C12 |

100NF |

Capacitor |

|

C13 |

100NF |

Capacitor |

|

C22 |

100uf |

Polarized Capacitor |

|

C23 |

100uf |

Polarized Capacitor |

|

D1 |

PMLL41SOD80C |

High speed diode |

|

D3 |

PMLL41SOD80C |

High speed diode |

|

F1 |

5A |

Fuse |

|

IC1 |

LMV321M5 |

OP Amp |

|

IC2 |

7805DT |

Positive voltage regulator |

|

IC4 |

7806DT |

Positive voltage regulator |

|

JP1 |

8 Pin male |

Dig0-7 |

|

JP2 |

6 Pin male |

Analog in |

|

JP3 |

8 Pin male |

Dig8-13 |

|

JP4 |

6 Pin male |

Power Arduino |

|

JP5 |

2 Pin male |

Reset |

|

JP6 |

2 Pin male |

Door |

|

JP7 |

2 Pin male |

Z-axis end-stop (not used) |

|

LED1 |

LED |

LED |

|

LED2 |

LED |

LED |

|

R1 |

1K |

Resistor |

|

R2 |

10k |

Resistor |

|

R3 |

47k |

Resistor |

|

R12 |

1K |

Resistor |

|

U$6 |

2 x 8 pin female |

A4988 |

|

U$7 |

2 x 8 pin female |

A4988 |

|

U$8 |

2 x 8 pin female |

A4988 |

|

U1 |

TC4425AV |

Mosfet Driver, low side |

|

X-MOT |

4 Pin male |

X-motor Connector |

|

X1 |

16 pin Ribbon Cable Connector |

Connector |

|

X3 |

2 Pin male |

Focus Signal |

|

X4 |

Connector Fuente 12V |

Connector |

|

Z-MOT |

4 Pin male |

Z-motor connector (not used) |

Important: All polarized capacitors of 16V.

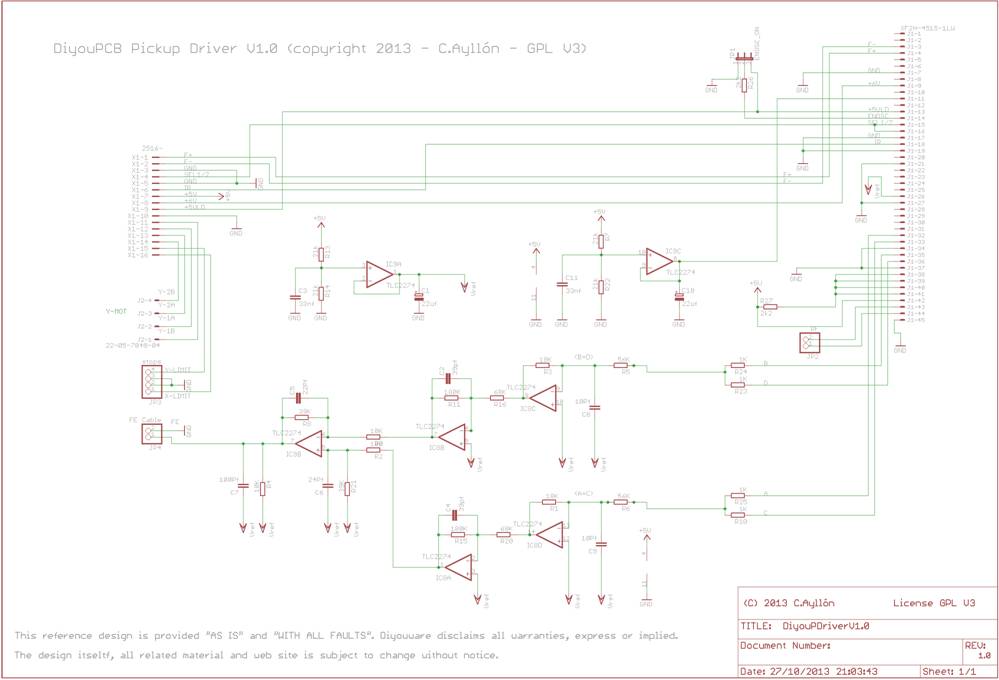

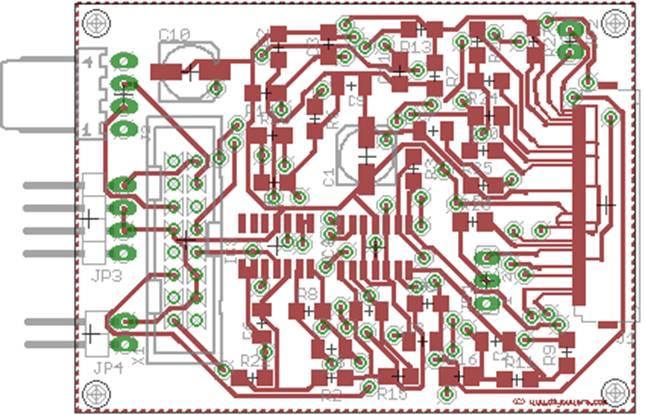

Assembling the Pickup Driver

The Pickup Driver is responsible of the interface between the Printer Controller Shield and the PHR-803T Pickup.

Its main function is to amplify and adapt the Focus Error (FE) signal from the data provided by the Pickup. It also houses the pickup FPC connector, the ribbon cable connector (that connects it to the PCS), the end-stops microswitches connectors, and the Y-axis stepper motor connector.

The picture above shows the PCB prototype that is slightly different from the final version.

As guidelines we indicated the most important steps:

- Print out the PCB

- Manufacture the PCB (cutting, etching, drilling, etc.)

- Solder the components with special attention to polarities

- Solder the pins and connectors

- Place the IC radiators

- Check that everything is correct

The most difficult point on the PCB assembling is to solder the 45 pins FPC connector. We have used the following trick with good results:

- Put the connector in place on the PCB.

- Solder the two connector tabs used to secure it to the PCB

- Verify that all the pins are aligned

- Apply abundant flux to the tracks and solder them with little heat. Do not heat too much because the connector would melts.

The circuit has a jumper which allows you to enable/disable the laser oscillator. It have to be connected through the resistor.

It is not necessary to solder the RF signal connector as it's not used.

The BOM to build this PCB is the following:

|

Pickup Driver V1.0 |

|

|

|

Component |

Value |

Description |

|

C2 |

39pf |

Capacitor |

|

C3 |

33nf |

Capacitor |

|

C4 |

39pf |

Capacitor |

|

C5 |

22Pf |

Capacitor |

|

C6 |

24Pf |

Capacitor |

|

C7 |

100Pf |

Capacitor |

|

C8 |

10Pf |

Capacitor |

|

C9 |

10Pf |

Capacitor |

|

C11 |

33nf |

Capacitor |

|

C1 |

22uf |

Polarized Capacitor |

|

C10 |

22uf |

Polarized Capacitor |

|

J2 |

4 Pins male |

Y-motor connector |

|

X1 |

16 Pins ribbon cable connector |

Ribbon cable connector |

|

J1 |

XF2H-4515-1LW |

FPC Pickup Connector |

|

JP1 |

2 Pin |

Laser OSC. Jumper |

|

IC8 |

TLC2274 |

Op Amp |

|

IC9 |

TLC2274 |

Op Amp |

|

JP2 |

2 Pin male |

RF Signal |

|

JP3 |

4 Pin male |

End-stops |

|

JP4 |

2 Pin male |

Focus signal (FE) |

|

R1 |

18K |

Resistor |

|

R2 |

10K |

Resistor |

|

R3 |

18K |

Resistor |

|

R4 |

10K |

Resistor |

|

R5 |

56K |

Resistor |

|

R6 |

56K |

Resistor |

|

R7 |

22k |

Resistor |

|

R8 |

39K |

Resistor |

|

R9 |

10K |

Resistor |

|

R10 |

1K |

Resistor |

|

R11 |

180K |

Resistor |

|

R13 |

22k |

Resistor |

|

R14 |

22k |

Resistor |

|

R15 |

180K |

Resistor |

|

R16 |

68K |

Resistor |

|

R20 |

68K |

Resistor |

|

R21 |

39K |

Resistor |

|

R22 |

22k |

Resistor |

|

R23 |

1K |

Resistor |

|

R24 |

1K |

Resistor |

|

R25 |

1K |

Resistor |

|

R26 |

2k2 |

Resistor |

|

R27 |

2k2 |

Resistor |

Important: All polarized capacitors of 16V.

After this stage you should have finished the printer electronics.