More on conductive inks and bowden hot-end support

We are still working on the idea of making conductive inks.

Right now we are focused on two directions: first, test a new copper nanoparticle ink which we recently brewed, and second, find an expert who help us to make silver conductive inks, just for testing, we don't need too much, a few ml will be enough.

We published some messages in chemical forums but we have not answers yet.

We think we have some interesting ideas about how to improve the traditional PCB manufacturing process using these inks with TwinTeeth and it seems nanoparticles are cool now. There is at least two companies which recently launched professional PCB ink printers which uses silver and copper nanoparticles inks.

This week Nano Dimension, filled a patent application for a new copper nanoparticles ink which they say improves the oxidation resistance of the nanoparticles. Copper nanoparticles rapidly oxidize in contact with air creating cooper oxide which is a bad electricity conductor. Silver nanoparticles also oxidize but silver oxide is a conductor. In fact it is used as a fine grained conductive paste filler. This is an important difference, and also that silver is the best electricity conductor after graphene.

Another interesting property of silver and many silver compounds is photosensibility. It is used for example in analogue photography and radiography. Even silver nanoparticles can be sensitized using a laser which is very interesting for our goals.

For all these reasons we also want to test with silver nanoparticles ink, but we don’t want to make it because we have too many battlefronts opened. Anyway if we see nobody can help us we will do it.

From our side, last week we made a new copper nano-particles ink using Polyvinylpyrrolidone (PVP). In theory PVP preserves the nanoparticles from oxidation because it covers the particles with a thin polymer film which can be removed later using a flash or a laser. We want to test it with our laser to see if it is powerful enough to activate the particles and make them conductive.

The formula is easy to do it and the chemical components are safe enough to try it in our kitchen. You have here a Robert Murray's video about how to make this kind of ink using the Polyol method.

We don't have chemical lab equipment (and we are not interesting to acquire it) so we had to improvise a lot. For example, Robert uses a sonicator in the original formula, but we don't have such device. Instead we tried using microwaves (one or two seconds into the microwave oven) and it works fine. How we know it works? Because the solution changes of colour from yellow, orange, brown and finally copper colour. When it has this colour it means the nanoparticles are ready.

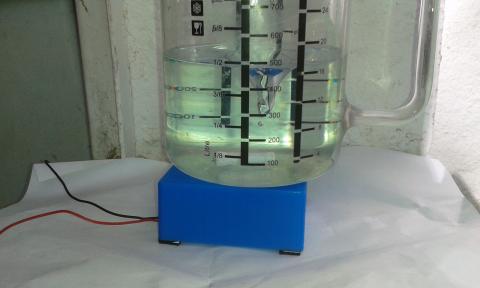

This is how the ink looks in its PVP bath:

This kind of ink is not conductive itself until it's activated with photonic energy. In theory the PVP which cover each particle is photosensible and react to intense light. Next step is try shooting it with our 405nm laser.

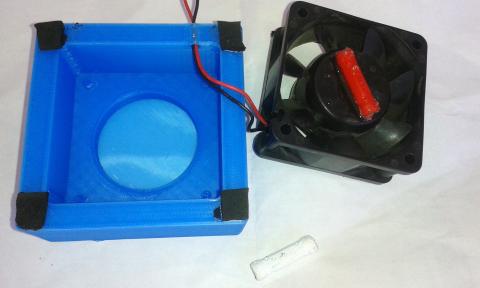

We also made a DIY magnetic stirrer using an old computer fan, a 3D printed part and some neodymium magnets. Here it is:

PCB vias trick in the media

It seems our last article about making blind PCB vias has had some repercussion in the media:

http://hackedgadgets.com/2015/11/22/pcb-vias-made-using-conductive-ink/

http://www.electronics-lab.com/making-pcb-vias-using-conductive-ink/

http://hackaday.com/2015/11/23/easier-pcb-vias-using-conductive-drill-bit/

http://dangerousprototypes.com/2015/11/23/making-pcb-vias-with-conductive-ink/

http://makerfeed.net/article/making-pcb-vias-with-conductive-ink

Thanks guys for published it and thanks also all the readers who sent us questions about it.

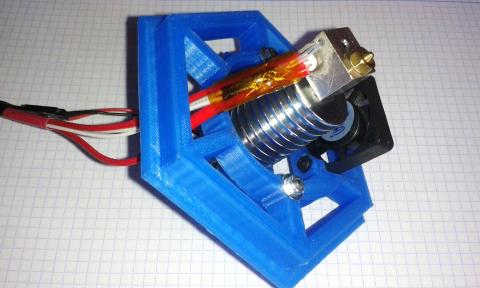

Bowden style hot-end support

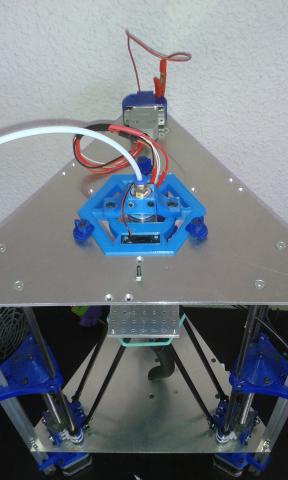

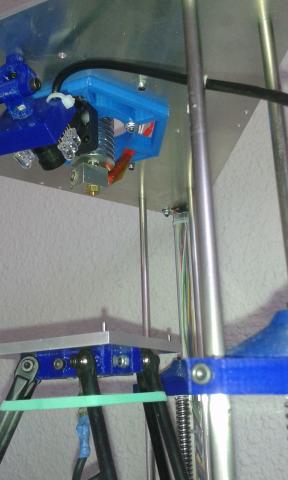

We also had time to design a new toolhead for a Bowden all-metal E3D type hot-end.

Some people asked us if we could support this kind of hot-end because actually it's possible to buy cheap Chinese versions at eBay for less than $15. So we designed a new plastic holder for use it on TwinTeeth.

The actual 3D printer Toolhead kit uses a direct drive extruder and a J-Head type hot-end which is also very popular. We will continue support it but now you can also use a bowden type if you want. We will include the .stl files it in the next release of the blue-prints and parts.

New version of TwinTeethMC

Finally, we are refactoring the TwinTeethMC code to adapt it to new versions of Control IP5 and Processing. We will also release them in the following weeks together with the ULPs and firmware modifications we did to make blind vias with conductive ink.

That's all for the moment. Thanks!

- Inicie sesión o regístrese para comentar